bda connectivity and Conyar cooperate on the commercialization of CNT cables manufactured using the latest innovative, proprietary production process.

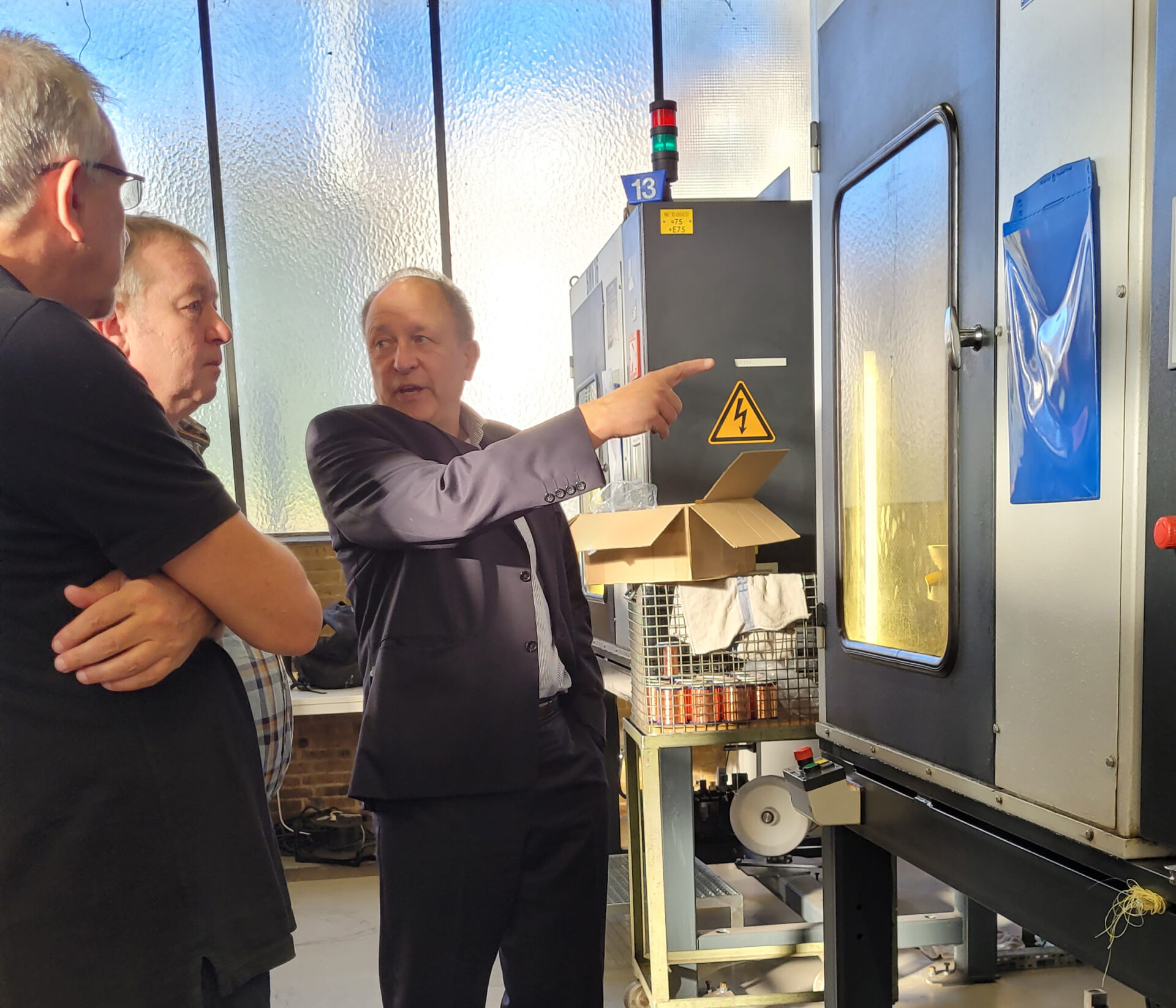

Recently, bda connectivity GmbH and Conyar BV started cooperation on the development, production and sale of cables made of Conyar fibers made of Carbon NanoTubes (CNT).

Cables made of Carbon NanoTube fibers have several advantages over conventional cables. While they transfer information just like copper cables, due to their carbonic structure, they weigh only a small percentage of a conventional cable. Therefore, they are the perfect choice for usage in aeronautics and astronautics as well as in formula 1 and e-mobility, where removing every gram can be crucial for the success of a project.

In the past, many companies had tried to work on cables made of Carbon NanoTubes. However, until today, we did not find any success story in the industrial usage of CNT in the conductor of a cable.

Only until now…

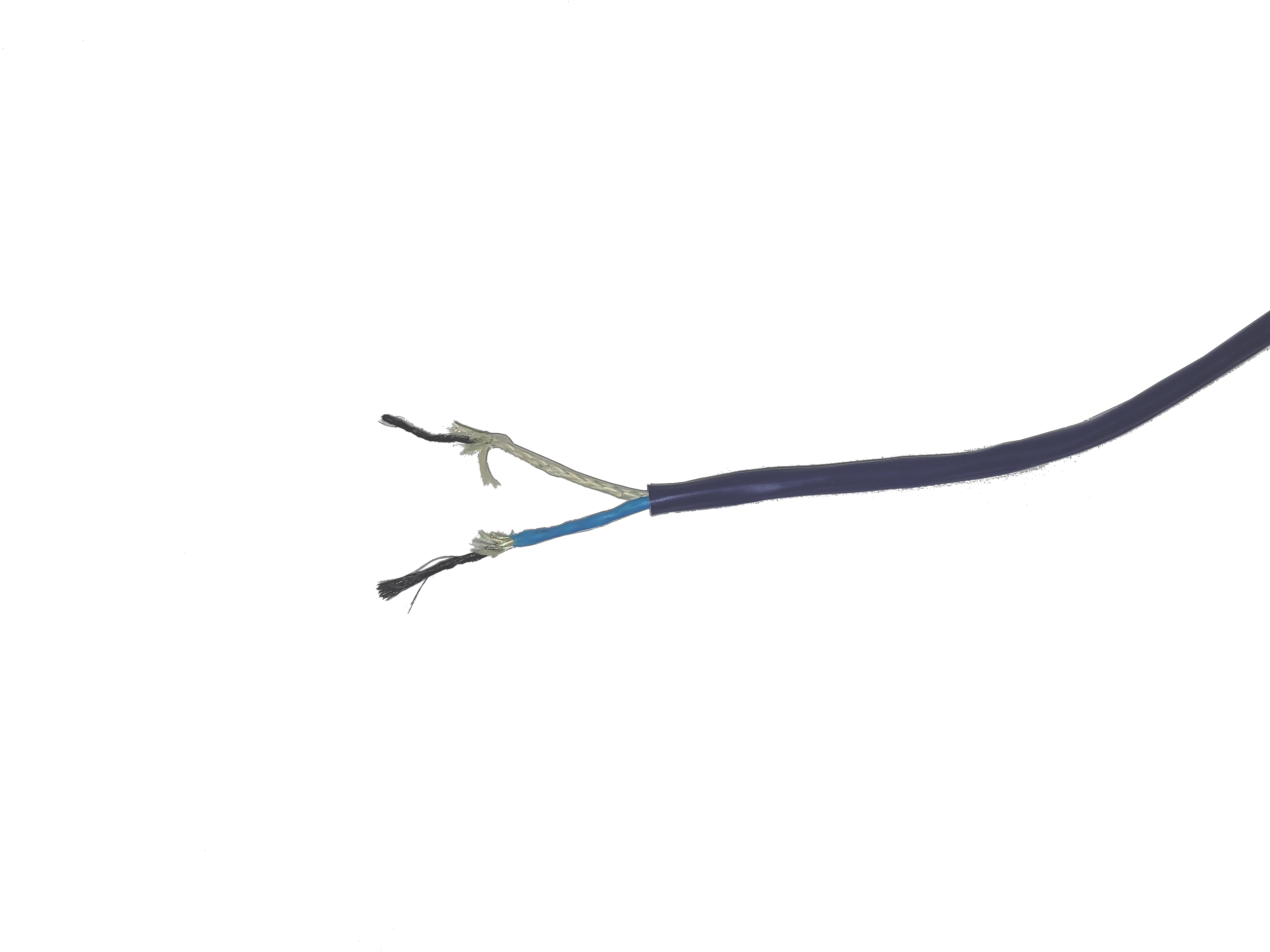

In the last few months, bda connectivity GmbH and Conyar BV, have successfully developed a process to bring the CNT yarn into a cable and thus make it available for practical use. Along with its low weight the cable construction provides enhanced resilience to fatigue. The CNT cable can be used in commercially available lengths, e.g. for fitting out aircrafts. Therefore, it can be used in high frequency technology, as a switching wire or electrical conductor.

The cable has several features that make it easily to implement in projects:

• The conductor can be easily contacted by crimping or with a conductive adhesive.

• The conductor is safely anchored in the cable without the danger of slipping out.

• The polymer insulation can be easily removed by detaching the sheath and insulation layer without sticking to the CNT material.

• Consequently, the bda-Conyar cable can be installed in the same way as a conventional cable.

The aim of the collaboration is to make a revolutionary technology available for practical use. Mr. Marcin Otto, CEO of Conyar BV, says about the cooperation: “Having this energetic and resourceful partner, bda connectivity GmbH, is for us a long awaited step in marketing Conyar™.”

Through the innovative process it is now possible to convert high-tech products and use them where weight plays a critical role. The companies wanting to decrease weight of their product can order ready-to-use cables. The further spread of the CNT cabling will reduce the production costs and make the technology available to a broader public.

Eike Barczynski, owner and managing director of bda connectivity, says that “the reduction of weight is a big issue in many industries. Thanks to the bda-Conyar technology we now have passed a new milestone in reducing the cable weight. This will lead to new dimensions in the usage of CNT.”

Just as the development of fiber optic cables has become a successful alternative to copper wires in the field of data technology, CNT cables can be used as a preferred alternative to switching wires or high-frequency lines. Less weight results in less energy consumption and thus can help to make products more energy-efficient and more environmentally compatible as well.